3D Laser Scanning

Create the digital twin of your manufacturing facility, factory or plant, improve operations, safety, maintenance and collaboration across your workforce.

The Digital Twin or smart factory has become the vision for every modern manufacturer. Modern manufacturers 3D laser scanning specialists, which is where we come in.

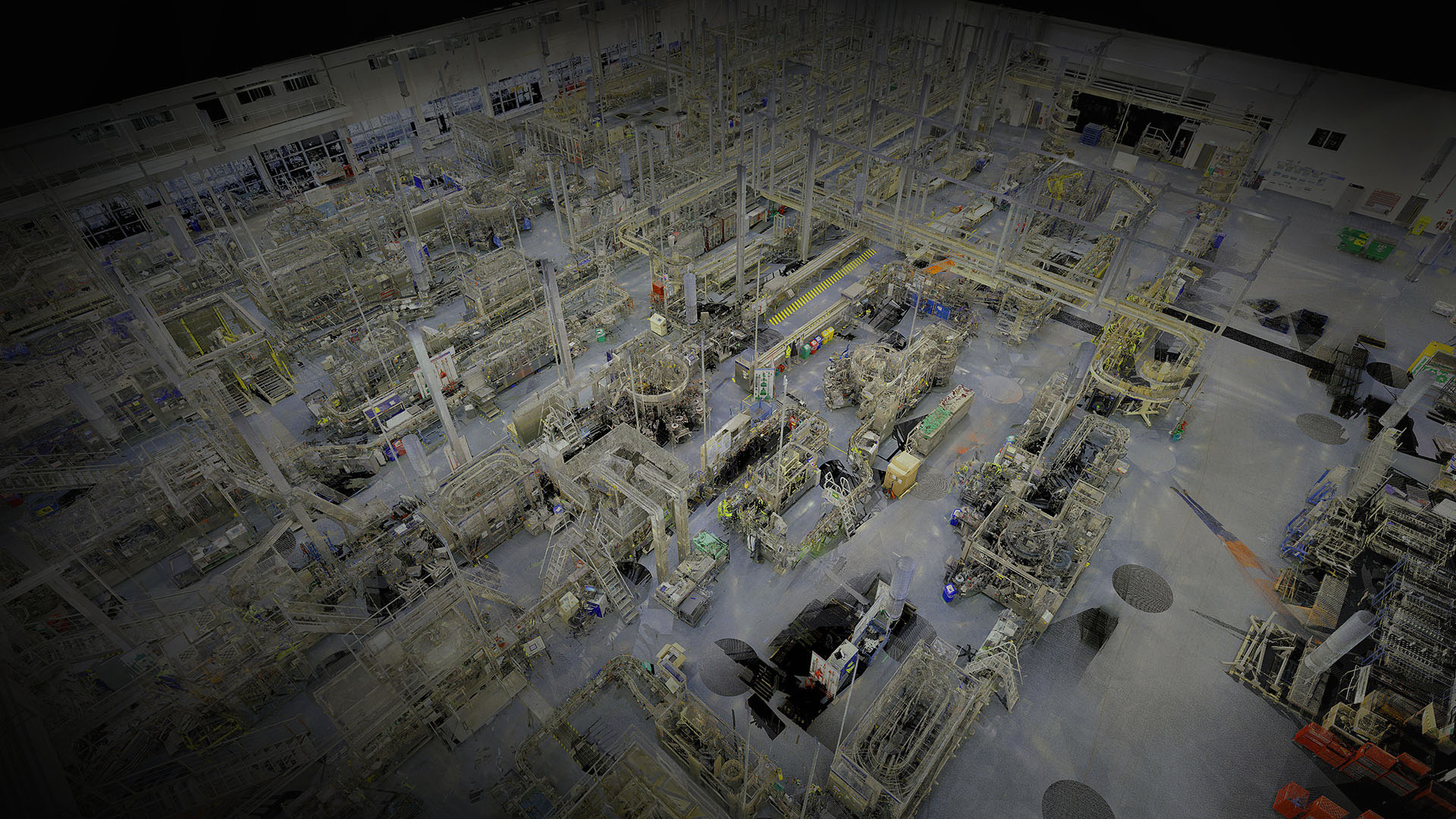

3D laser scanning provides a method to digitise complex facilities very quickly with minimum disruption. The results can be a 3D point cloud, 360° panoramic images and virtual tours or 3D models.

Luminous use the latest mobile slam enabled 3D scanning systems to provide rapid site capture. Once scanned data is hosted and accessed in the cloud through the Luminous Digital Twin portal providing real-time access and virtual walkthroughs.

Increase in knowledge retention

Increase in engagement with XR

Increase in confidence

![]()

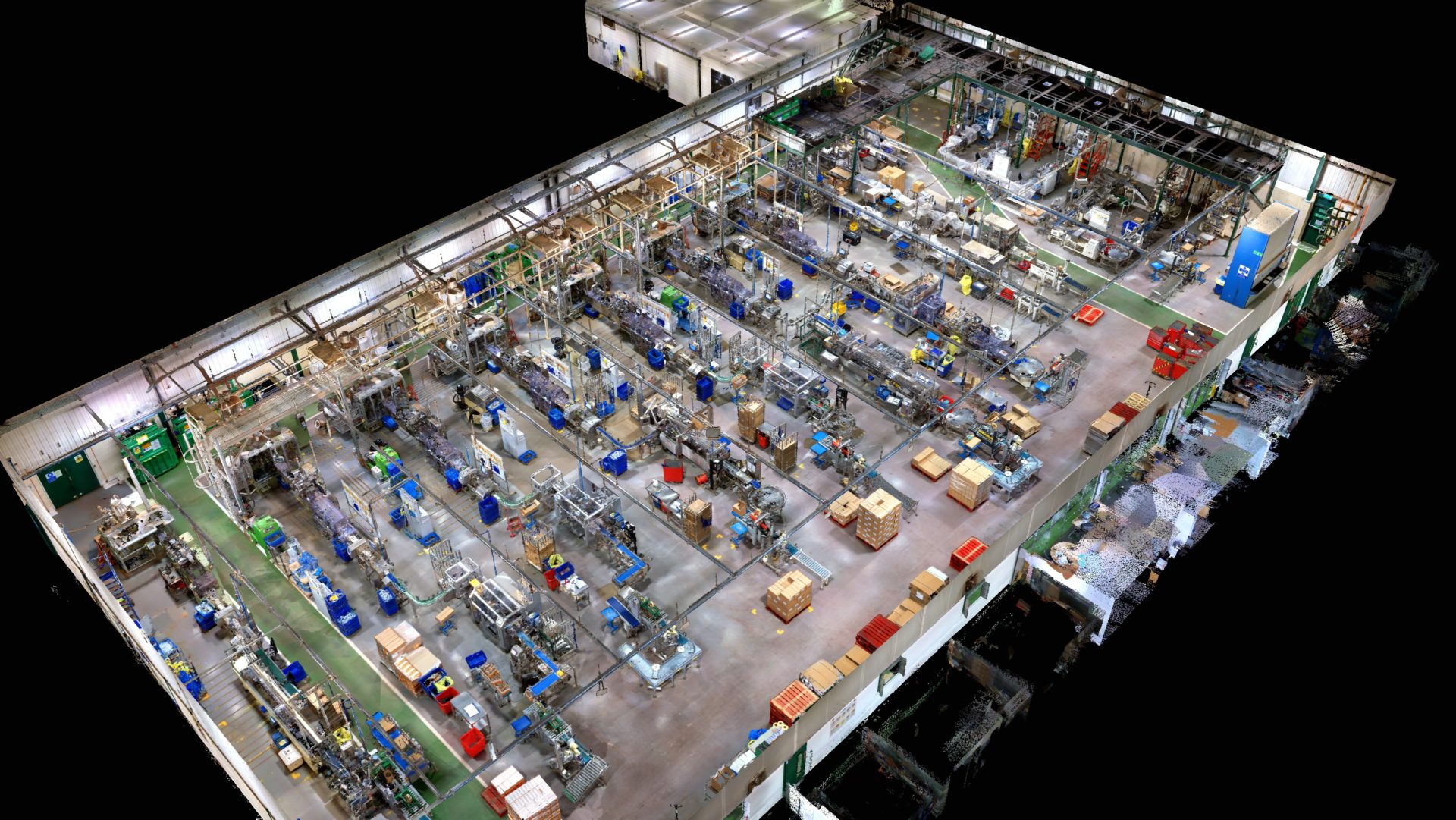

Luminous provides a managed service for all your 3D scanning and reality capture needs. Once a baseline scan of the full facility has been captured our team will maintain this data with regular visits to capture any changes as the facility changes over time.

This gives you the peace of mind that what you’re looking at is always correct with a single source of truth. Scanning is carried out using the latest mobile scanning technology allowing large live sites to be captured quickly and efficiently with zero disruption to employees and production.

The scanning creates a 3D Point Cloud which comprises of millions of dimensionally accurate points of data and 360° degree panoramic images which can all be accessed through a secure cloud-based portal.

Factory documentation is often inconsistent and only accessible to experts using specialist software. In partnership with NavVis and their IVION solution, stakeholders can interact with realistic digital twins of their factories via the cloud through an easy to use browser-based portal.

Access all of your factories from one account. Easily switch between and search for sites from a central dashboard

Edit and download sections of a point cloud in different file formats, so you can edit your point clouds and import them into other software programs. Make a selection in the point cloud with the 3D crop box to only download what you need.

An easy to use, scalable content management system for adding geo-tagged information and media to 3D scans. Users can right-click anywhere on the screen to add and view this information as points of interest.

360° immersive images are not just digital images. The pixels in these images are enriched by laser scans, which makes it possible to interact with scanned spaces as if you are on site, including taking accurate point-to-point measurements.

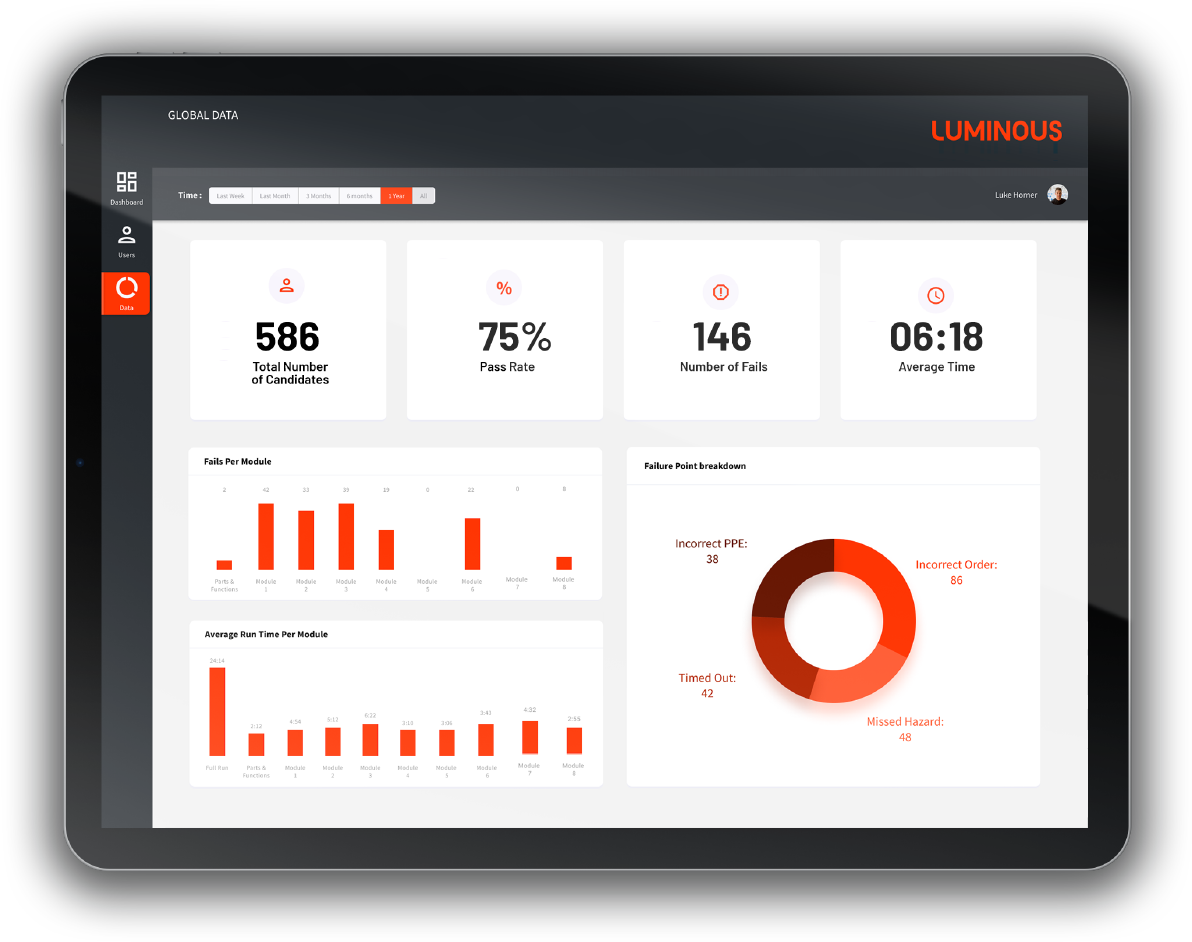

To manage students and classes we’ve created a secure web-based portal. This portal allows the administration and assessment of students and the deployment of training content to devices.